India, with its $108 billion fashion and textile market, is both a major player in global fashion and a significant contributor to environmental challenges. The country produces over 62 million tons of waste annually, with textiles accounting for a substantial share. Globally, the fashion industry generates 92 million tons of waste each year and is responsible for 10% of carbon emissions. India’s population growth and rapid urbanization are projected to double waste levels by 2030, making sustainability in fashion and packaging an urgent priority.

However, this challenge presents an opportunity for India to pioneer innovative, scalable solutions that combine its traditional textile heritage with modern sustainability practices. By adopting circularity—a model emphasizing reuse, recycling, and waste minimization—India can revolutionize its approach to fashion and packaging while contributing to global climate goals.

India’s rich textile heritage and evolving consumer preferences create a unique opportunity to adopt long-term design strategies for sustainable fashion. With increasing awareness of environmental issues and government initiatives like the Extended Producer Responsibility (EPR) framework, the fashion industry must focus on durability, care, customization, and circularity. Here’s how these strategies can be implemented within the Indian context:

Durability resonates with Indian consumers who value garments that withstand repeated use, reflecting a “value-for-money” ethos. The growing popularity of thrift stores and rental platforms also underscores the need for robust products.

Actions

In action inspiration

Indian brands can draw inspiration from Lacoste’s durability protocols and Uniqlo’s fabric innovation to create long-lasting apparel suited for local climates.

Indian consumers often hold emotional connections with their clothing, particularly in traditional attire like sarees and sherwanis. Encouraging care and repair aligns with this sentiment while promoting sustainable practices.

Actions

In action inspiration: Inspired by Marks & Spencer and Primark, Indian brands could offer repair kits for commonly worn items such as kurtas and denim.

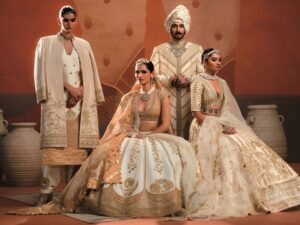

With a culturally diverse customer base, India requires garments adaptable to varying body types and regional preferences. Customization and adjustability can enhance emotional and physical longevity, particularly in festive and formal wear.

Actions

In action inspiration

Indian brands can emulate Good American’s stretchable denim or Marfa Stance’s modular outerwear, integrating these principles into ethnic and fusion wear.

The rental and resale markets in India are on the rise, especially for occasion-specific attire like bridal wear. Circular models offer a sustainable solution to address the fast fashion crisis.

Actions

In action inspiration

Inspired by Patagonia and HURR, Indian retailers could integrate circularity by reselling gently used garments or creating rental spaces for designer ethnic wear.

As the Indian fashion industry grapples with its environmental impact, the need to design products that can safely disappear at the end of their life has never been more urgent. With the global textile industry contributing 92 million tonnes of waste annually, the challenge for India is to innovate sustainable solutions that align with its unique socio-economic and cultural landscape.

This section explores three pivotal strategies to revolutionize Indian fashion while tackling waste and pollution.

India’s textile market is heavily reliant on non-biodegradable materials like polyester and nylon, widely used in sarees, sportswear, and formal attire. While these materials are durable, they are resistant to decomposition, exacerbating landfill waste. Innovations in biodegradable alternatives, however, offer promising solutions.

Composting offers an eco-friendly disposal method for textiles, converting waste into resources for soil enrichment. While India has a strong tradition of natural fibers like cotton and silk, synthetic blends dominate the market, delaying decomposition and releasing harmful chemicals.

Designing garments for easy disassembly ensures cost-efficient recycling and minimizes landfill contributions. India’s vast market for affordable fashion, however, presents unique challenges in adopting such innovative approaches.

India generates over 62 million tons of municipal solid waste annually, of which only 30% is processed, according to recent estimates. With urbanization and consumption trends on the rise, this figure is expected to double by 2030. This makes the following framework not just a necessity but an opportunity for Indian businesses to innovate and redefine waste management practices.

Indian businesses must adopt long-term strategies that integrate ecological, social, and cultural values. For instance, envisioning a legacy beyond profits can align brands with India’s sustainability ethos. Backcasting—a method that starts with a desired future and works backward—can guide businesses to establish actionable plans.

Case Example: A hypothetical Indian start-up could draw inspiration from Sweden’s Benim Denim, which planned its shutdown after using a single roll of repurposed deadstock denim. This approach could resonate with Indian consumers who value sustainability and transparency.

Designing products with end-of-life in mind is pivotal. Indian brands can adopt biodegradable materials and invest in research collaborations with academic institutions. Sustainable packaging, like edible bowls by South Africa’s Munch Bowls, can find applications in India’s robust food delivery sector, reducing single-use plastics.

In India, where informal waste recycling is prevalent, businesses can support localized waste disposal solutions. Collaborating with municipalities to establish recycling hubs or launching take-back programs can create sustainable loops.

In Action: Inspired by The North Face Renewed program, Indian apparel brands could incentivize customers with credits for returning old garments, enabling refurbishment or recycling.

Small changes can lead to significant impact. Indian businesses can explore multi-purpose products, like large-format, gender-inclusive personal care items, reducing the need for multiple SKUs.

Future Potential: A fragrance brand could adopt biodegradable packaging that doubles as a usable product, akin to Arpa Studios’ glycerine soap containers. Such innovations resonate with India’s cost-conscious and eco-aware consumers.

In the Indian textiles and fashion ecosystem, tactile, furry, and plush materials have captured consumers’ desire for comfort and indulgence. Yet, these materials pose environmental and ethical dilemmas, such as animal welfare concerns, microplastic pollution, and carbon emissions. Addressing these challenges in the Indian context requires innovative strategies that align with global insights.

Here’s how buying and design strategies, natural fibers, and bio-based innovations can transform India’s textile industry into a model of sustainability and circularity.

India’s diverse textile industry, from handlooms to high-tech manufacturing, has a unique opportunity to lead the sustainability and circularity movement. By integrating global best practices with local innovations, the industry can reduce its environmental footprint while maintaining its rich heritage.

This dual approach not only addresses consumer preferences for “Feel Appeal” but also positions India as a leader in sustainable fashion solutions, paving the way for a circular and inclusive textile economy.

In the global discourse on sustainability, India’s role in addressing the challenges posed by packaging waste stands out as both a necessity and an opportunity. With its vast population and burgeoning consumer base, the country generates significant amounts of packaging waste, much of which stems from single-use plastics. As global and domestic policies evolve to combat climate change, the shift toward circular packaging presents a transformative solution.

Circular packaging emphasizes sustainability by reducing waste, rethinking materials, and reimagining the lifecycle of packaging. According to the Ellen MacArthur Foundation, adopting circular packaging systems globally could reduce CO₂ emissions by 69% and waste by 76%, highlighting the immense potential for environmental impact.

These key strategies provide a blueprint for innovation in packaging:

For instance:

For example, setting up QR-code-based platforms like Recycle Check could guide consumers on how to dispose of packaging responsibly.

> Material Innovation

Innovative materials such as those developed by Shellworks or Empa—derived from waste like tapioca starch or beer brewing residue—align with India’s agricultural base and abundant food processing industries. Leveraging these materials for localized use could reduce dependency on virgin resources.

> Returnable Packaging Systems

Inspired by global practices, Indian e-commerce and food delivery giants can explore returnable packaging. Models like Burger King’s returnable packaging pilot in Germany could be adapted to urban Indian markets, fostering a culture of reuse.

The adoption of circular packaging isn’t just about compliance with global trends; it’s a necessity for India’s environmental resilience. With nearly 46% of plastic waste in India coming from packaging, transitioning to circularity can mitigate the environmental degradation caused by landfills and water pollution.

Legislation such as India’s Plastic Waste Management Rules already emphasizes extended producer responsibility (EPR). Circular packaging innovation aligns seamlessly with these regulations, offering businesses a path to compliance and sustainability.

India has the opportunity to emerge as a leader in circular packaging by integrating traditional practices with cutting-edge innovations. By adopting refillable systems, biodegradable materials, and scalable recycling technologies, the nation can set benchmarks for sustainable development while contributing significantly to global climate goals. Circular packaging is the cornerstone of a greener, more resilient India.

India stands at the threshold of a transformative shift in fashion and packaging. With the integration of long-term durability strategies, repair-friendly designs, customization, circular business models, and sustainable packaging, the nation can redefine its textile and design narrative.

The stakes are high: India’s contribution to global emissions and waste cannot be ignored. However, its rich textile heritage, coupled with a burgeoning tech-savvy population, positions the country as a leader in sustainable innovation. By embracing circularity, Indian fashion and packaging industries can not only mitigate environmental impact but also set a global benchmark for inclusive and sustainable growth.

India’s journey toward circularity is an opportunity to shape a resilient and eco-conscious future.

The time to act is now.

This article is an adapted version of a feature originally written by The Knowledge Company/WGSN exclusively for IMAGES Business of Fashion. For more such content, log on to www.imagesbof.in